|

|

|

TetraTek ColdMaster

Walk-In

Rooms

Environmental walk-in chambers

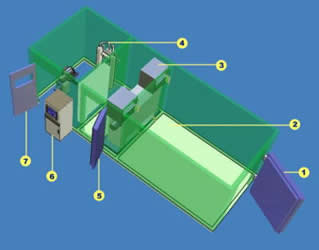

State of the Art, mechanically refrigerated, walk-in and drive-in environmental

test equipment rooms created to exactly match your requirements. In partnership with

the leading manufacturer of prefabricated walk-in rooms in the Western United

States, we offer the most modern and technically sophisticated,

cooled, heated and humidity controlled, insulated structures available.

The

TetraTek

ColdMaster Walk-in Room

is a stainless

steel interior sectional urethane foam enclosure refined to optimize your

testing experience. These chambers provide the professional backdrop to show off

your products and verify their proper operation in various temperature and

humidity environments. They allow you to check proper system operation in a real

world thermal, wet, or dry environment without leaving the comfort or security

of your factory.

Each system is carefully considered to provide

you with maximum performance consistent with easy maintainability and long term

return on your investment.

Every component is selected for proven

reliability and suitability. Machinery and instrumentation are industrial

quality and high efficiency. Color digital displays, Ethernet communication,

solid state sensors and instrumentation, automatic monitoring, programmability,

and extra precautions for dependability in refrigeration and system performance

are standard.

Each facility, matched to your requirements.

We

invite you to request a free analysis of your needs.

Advanced Control:

-

Touch screen or PC based display.

-

PLC or software and PC Control.

-

Fully modulating cooling valves.

-

Digital record keeping.

-

Multiple high and low alarms.

-

Time stamp of system events.

-

Ethernet Interface.

-

Stored programmable profiles.

-

Complete Software listings.

Advanced Construction:

-

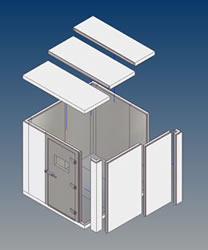

A heated frame in-fitting or flush sealed main

door to positively seal the chamber workspace.

-

TetraTek s exclusive, triple

compartment (workspace, conditioning & machinery) construction.

-

Factory pre-assembled conditioning packages

slip right in on site.

-

Industrial rated machinery packages mount

directly to your concrete pad.

-

A thermally sealed access door allows easy

inspection and maintenance of system conditioning equipment.

-

Touch screen color and

PLC or PC-based

software

driven control systems automate record keeping and control.

-

An acoustically isolating door with a large

window helps keep machinery noise out of your laboratory.

Advanced Features:

-

Rigid interlocking panel, Underwriters

Laboratories Certified, closed cell urethane foam insulation.

-

At least three heavy duty cam-action locks in

each side wall.

-

Interior stainless steel 20-gauge wall and

ceiling panels and 16-gauge floor panels rated at 650 PSF.

-

Exterior 24-gauge pre-painted galvanized steel

wall panels with formed stainless steel floor trim coving.

-

Built-in gaskets between all panels with RTV

sealant applied during chamber installation.

Standard Temperature Ranges are:

-

-0 to 60 C, single stage remote air or

water-cooled refrigeration.

-

-0 to 85 C, single stage remote air or

water-cooled refrigeration.

-

-20 to 85 C, single stage remote air or

water-cooled refrigeration.

-

-30 to 85 C, single stage remote air or

water-cooled refrigeration.

-

-65 to 85 C, cascade, two stage water cooled

refrigeration.

Standard Humidity Ranges are:

-

No humidity capability, temperature only.

-

20 to 95% RH, limited to 5 C dew point

(mechanical dehumidification).

-

10 to 95% RH, limited to 0 C dew point (recirculating

desiccant drier).

-

5 to 95% RH limited to -5 C dew point

(compressed air desiccant drier).

Standard access door Sizes are:

-

30-inches wide x 78-inches high clear.

-

34-inches wide x 78-inches high clear.

-

42-inches wide x 78-inches high clear.

-

60-inches wide x 78-inches high clear.

Standard interior workspace heights are:

-

6 -10" inside. No inside suspended

ceilings or air ducts available.

-

7 -10" inside. Ceilings and ducts OK.

-

8 -10" inside. Ceilings and ducts OK.

-

9 -10" inside. Ceilings and ducts OK.

Standard interior workspace sizes are:

-

The smallest size available is 7 -6"

wide by 7 -6"deep inside.

-

Sizes are available in increasing increments

of 5.75-inches.

-

Maximum standard size is 42 -6" wide by

42 -6" deep.

-

Custom sizes are available.

-

Custom and larger projects require measurement

of your site.

Optional airflow patterns include:

-

Fully perforated ceiling with lower rear wall

air return.

-

Partial perforated ceiling with lower side

wall return ducts.

-

Center ceiling supply duct with lower rear

wall air return.

-

Center ceiling supply duct with lower side

wall return ducts.

Available options include:

Doors Windows and

Accessories:

-

Horizontally sliding power doors on

Temperature Chambers above -20 C only.

-

Bi-parting doors on Temperature Chambers above

-20 C only.

-

Clear Vinyl strip curtain interior doors on -0

to 60 C temperature models only.

-

Man access doors 30-inches by 78-inches in the

workspace.

-

Dual door lighted airlock compartments for

upset free man access during testing.

-

Heated 15-inch x 20-inch wide windows in the

chamber side walls or doors.

-

Internal stainless steel cart bumper rails.

-

Exterior chamber corner and door crash guard

reinforcement and protection.

-

Depressed floor to allow flush roll-in of test

products. Requires a special slab.

-

Recessed interior vapor proof or fluorescent

lights.

-

National Sanitation Foundation Standard Number

7 construction.

Feed-throughs:

-

TetraTek exclusive square Plexi-glass

feed-throughs on >-20 C models.

-

Permanent electrical and fluid bulkhead

connectors.

-

Round feed-throughs with plugs in 3-inch,

4-inch and 6-inch sizes.

Conditioning Systems:

-

Variable speed PLC controlled air circulation

blower motors.

-

Outside air injection with positive motorized

valve isolation.

-

Compressed air desiccant drier

dehumidification.

-

Recirculating regenerated air drier

dehumidification.

-

TetraTek exclusive thermally clamped humidity

generator system.

-

Direct humidity sensing process sensors.

-

Complete refrigeration gauges on all systems

are Standard.

Test Fixturing and Instrumentation:

-

Stainless steel cantilever shelves, 16-inches

or 20-inches wide.

-

Roll-in product carriers and handling systems.

-

Environmentally rated circuit board card

cages.

-

Product load and test simulation electronics.

-

Ground fault electrical receptacles.

-

Product Ethernet and LAN connectors and

cabling.

-

Electronic, fluid, and hydraulic test systems.

-

Data acquisition and product monitoring

equipment.

-

Chamber temperature and humidity circular

chart recorder.

-

Chamber temperature and humidity digital strip

chart recorder.

|