|

|

|

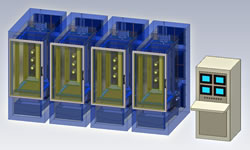

Temperature Chambers, Humidity

Chambers,

Burn-in Chambers, and Stress Screening Chambers

Environmental Test Chambers

In a class by themselves,

TetraTek environmental test chambers use laboratory proven subsystems to produce

consistent test results.

Each component is carefully balanced with all others to form a perfectly working

whole. Extensive calculation, detailed engineering analysis, precision

assembly, and thorough testing are TetraTek hallmarks.

TetraTek chambers include high volume air circulation systems to maintain

inside air temperature uniformity, assure test to test repeatability, and maximize testing effects.

These chambers are available with large cooling

systems to allow rapid temperature cycling or to handle huge product

live loads. All can be mechanically or liquid nitrogen cooled. They can even be

furnished with a central chiller cooling system for multiple chamber

installations. Instrumentation options include state of the art digital

process controls, touch screen HMI's (human machine interfaces) and digital

recorders and data loggers.

Temperature Ranges Available are:

-

Maximum available: -185 to +538 C (-300 to +1000 F)

-

Range 1: -30 to +60 C (-22 F to +140 F)

-

Range 2: -37 to +93 C (-35 to + 200 F)

-

Range 3: -37 to +177 C (-35 to +350 F)

-

Range 4: -73 to +177 C (-100 to +350 F)

Humidity Ranges Available are:

-

No humidity capability, temperature only.

-

20 to 95% RH, limited to 5 C dew point

(mechanical dehumidification).

-

10 to 95% RH, limited to 0 C dew point (recirculating

desiccant drier).

-

5 to 95% RH limited to -5 C dew point

(compressed air desiccant drier).

-

5

to 95% RH limited by a -50 C dewpoint

(compressed air desiccant drier).

Available accessories include built in; test fixturing, product supports, relay

rack rails, shelves, card cages, product wiring, product piping, and custom product

connectors. Test simulation load boards and external exercising

electronics can be directly wired to internal supports or card cages.

Please request a free analysis of your needs.

You may also wish to

review our

Request for TetraTek Application Assistance

on our

Literature Page

. Additional

information on our test fixturing and product testing capabilities is contained

on our

TestKing Page.

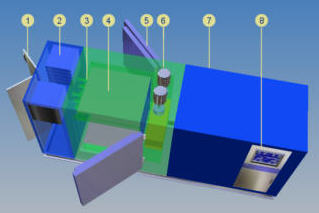

Ideal for electronic testing

Our TetraTek

Model BR40, Dual-Door Thermal Stress Screening Chamber,

features a full forty cubic feet (40" wide by

40" high by 43-1/2" deep) of workspace and BOTH FRONT AND BACK Chamber

access doors, 19-inch relay rack style mounting of test instrumentation, and

inside chamber rail mounting of your device test fixtures. You have

everything you need to successfully test your products, all in half the space

needed by conventional designs.

Conditioning equipment includes:

-

Vertical air flow for electronic

component, circuit board, and assembly testing.

-

Cooling by either a single stage or cascade,

non-ozone depleting, water cooled refrigeration system.

-

Heating by fast response nichrome electric

elements controlled by zero-cross-over solid state relays.

-

Fully proportional modulation of cooling (no

solenoids) for precise control of system conditions.

-

Optional humidification using a special

thermally clamped, fast response, TetraTek vapor generator.

-

Optional low

dew point dehumidification using a

heatless, regenerative, compressed air desiccant drier.

Advanced Features of the Model BR40:

-

Access doors with top and bottom recessed

locking cam-action locks and

19-inch EIA style drilled and tapped rails on

the front and back for mounting of test electronics.

-

Optional power supplies, instruments, and

distribution panels to power, stimulate, and monitor your devices under

test.

-

Optional access sleeves for convenient

connection to your test items.

-

Chamber workspace with both top and bottom

air distribution baffles to assure even air flow distribution around your test

items.

-

Front and rear, plug type, access doors with

heavy duty hardware and latches for a tight seal.

-

Dual counter-rotating blowers to assure a

uniform environment and even heat transfer around your test items.

-

System conditioning apparatus.

-

Control panel with touch-screen, 256-color,

human machine interface.

Operational Specifications:

-

Temperature range: Single stage system: -20 C to 150

C

-

Optional Temperature range: Cascade cooling system: -65 C to 150 C

-

Optional humidity range: 15 to 95% limited by a 0 C

dew point

-

Direct

relative humidity (RH) measuring sensor standard.

-

Desiccant drier dehumidification standard.

-

Standard heating rate:

-

-20 C to 150 C in 30 minutes empty.

-

Standard cooling rate single stage:

-

150 C to 0 C in 30 minutes empty.

-

Standard cooling rate cascade cooling:

-

150 C to -55 C in 60 minutes empty.

Quality Features Include:

-

Programmable Logic Control (PLC) process

control.

-

RS-485 communications interface.

-

A 10-inch color touch screen Human

Machine Interface (HMI).

-

A non-ozone polluting, water cooled,

refrigeration system.

-

Silfoss and silver soldered copper

refrigeration piping.

-

Hinged access panels and heavy duty

industrial hardware.

-

Programmable control of chamber

environmental profiles.

-

Digital display of system conditions and

control parameters.

-

Oil-tight illuminated master switch and

reset pushbutton.

-

A 300 series stainless steel continuous

heliarc welded interior.

-

A heavy gauge cold rolled steel outer

case and frame.

-

Refrigeration gauges, pressure switches

and safety sensors.

-

An average of 6-inches of vapor sealed

fiberglass insulation.

-

Two full opening, in-fitting chamber

access doors.

-

A separate high temperature safety

control.

-

Stainless steel door drip pans.

Normal required utilities are tower water at a

maximum temperature of 85 F and a minimum pressure of 20 psig, three phase

power, deionized water when optional humidity is selected, and drain. All

utilities except for electrical power are terminated on a convenient anodized

aluminum panel on the rear of the system.

Optional Humidity Systems

Feature:

-

A TetraTek stainless steel electric

heated vapor generator.

-

A dual tower, heatless, compressed air

desiccant drier.

-

A wide range precision direct relative

humidity sensor.

Available Options:

-

Discrete system process controls to suit

your preference.

-

A digital one or two pen strip

chart recorder.

-

A 24-hour or 7-day circular chart

recorder.

-

Burn-in rated power supplies,

distribution panels, and bus bars.

-

Environmentally rated shelves, card

cages, and supports.

-

Access ports, connectors, and feed-throughs.

-

Interior windows and lights.

-

Product load and test stimulation

electronics.

-

Data acquisition and product monitoring

equipment.

|