|

|

|

High Vacuum Cryogenic Shrouds

and Vacuum Systems

Thermal Base Plates, Thermal Shrouds,

and Space Simulators

TetraTek's

team of experts has over 30 years of experience in the

fabrication of Thermally Conditioned Base Plates, Thermal Shrouds, Space

Simulators, High Vacuum Systems, and matching Thermal Conditioning, Vacuum

Pumping, Fluid and Gas Circulating, and Instrumentation Systems.

Vacuum enclosures are available to operate from 1

x 10-7 Torr to atmospheric pressure and thermal conditioning systems are offered to produce

temperatures from almost absolute zero to 150 C (302 F). Fluid circulating

systems are available to cool and heat Base

Plates or Shrouds from -55 C to +150 C, while gas conditioning systems can cool

and heat from -185 C to 150 C. Cooling systems utilizing, cryo-engines or

liquid helium can reach temperatures as low as -263 C.

TetraTek Vacuum vessels

feature:

-

304 or 316 heliarc welded stainless steel

construction.

-

Electro-polished or

bead blasted inside surfaces.

-

Leak testing to 1 x 10-9 std cc/sec.

-

Standard Conflat, KF, ISO, or ASA type

flanges.

-

Roughing and/or gauge ports.

-

A sand or bead blasted exterior finish.

-

Stainless steel or aluminum slide or angle

valves.

-

Vacuum roughing pumps, filters and traps.

-

Vacuum monitoring and control instrumentation.

-

Process control instrumentation

with Touch Screen HMI.

Base Plates, Shrouds and Vacuum Subsystems:

-

High vacuum electrical

feed-throughs

-

High vacuum fluid feed-throughs.

-

Stainless steel and aluminum thermal shrouds.

-

Optically dense pumping ports.

-

Aluminum and copper base-plates.

-

Liquid nitrogen cooling systems.

-

Single stage and cascade refrigeration systems.

-

Fluid circulating systems.

-

Heating systems.

-

Gold

plated copper shrouds and base-plates.

-

Pressurized gas circulation systems.

-

Helium engine cooling

systems.

-

Cryopump

assemblies.

-

Turbomolecular

vacuum pump assemblies.

-

Thermocouple and

process sensor feed-throughs.

-

Vacuum automation and motor

drives.

-

Product and test handling

fixtures.

-

Data acquisition systems.

-

Optically dense traps.

Please request a free analysis of your needs.

You may also wish to

review our

Request for TetraTek Application Assistance

on our

Literature Page

. Additional

information on our test fixturing and product testing capabilities is contained

on our

TestKing Page

and additional information

on our Environmental Temperature Chambers, Humidity Chambers, Burn-in Chambers

and Stress Screening Chambers is contained on our

Environmental Page.

Advanced conductive

gold plated cryogenic shrouds

Our unique

TetraTek VacTek

copper shrouds are fabricated from

gold plated oxygen free, rolled, welded and plated copper. Inside one of our

electro-polished stainless steel vacuum vessels using some unique techniques

developed by TetraTek, and a commercial Helium Cryoengine, we are able to

achieve temperatures on the inner shroud surface of approximately 10 Kelvin without the use of a cryogenic

fluid such a

liquid nitrogen.

These systems are sometimes used for research in

low temperature cryogenics, space simulation, as an infrared background for

liquid helium cooled IR instruments, and for specialized materials research.

Copper thermal shrouds

feature:

-

Oxygen free copper rolled and welded

construction.

-

Vacuum rated paint on the inside surface of the inner shroud.

-

24-K pure gold plating for IR heat transfer

resistance.

-

Gold plated and stainless steel machined

hardware.

-

Optically dense openings or IR shields.

-

Black anodized aluminum product support structures.

-

Stainless steel hard-points.

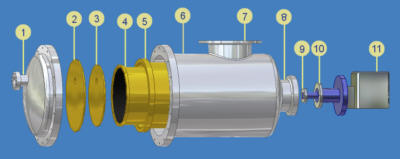

A

Typical TetraTek IR Sensor

Housing Features:

1. An electro-polished stainless steel

access door and optical inlet flange.

2. A copper outer shroud door, gold plated both sides .

3. A copper inner shroud door, gold plated and black painted inside.

4. A copper inner shroud, gold plated and black painted inside.

5. A copper outer shroud, gold plated both sides.

6. An electro-polished stainless outer vacuum shell.

7. An ASA flanged, stainless steel optical sensor interface

port.

8. A cryoengine stainless steel Conflat flange attachment port.

9. A cryoengine low temperature connection plate.

10. A cryoengine medium (liquid nitrogen) temperature connection plate.

11. A commercial cryoengine.

|